Mathematical model allows researchers to grow intricate microsculptures including vases and helices

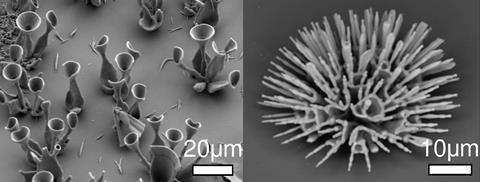

Silica-carbonate crystals can be grown into microsculptures thanks to a theoretical framework developed by US scientists. The miniscule vases, helices and hedgehog-like beam splitters could find applications as components in electronic or optical devices.

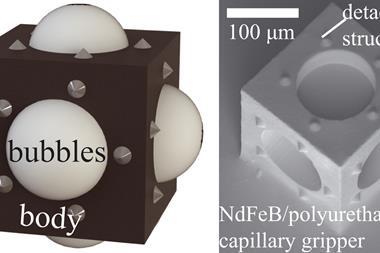

Micro-sized structures can be made by cutting away parts from a larger piece of material (lithography), by 3D printing or by colloidal self-assembly. But all of these methods have their drawbacks: lithography is difficult to scale up, 3D printing can’t accurately fabricate micrometre-sized structures and self-assembly usually only creates symmetric shapes.

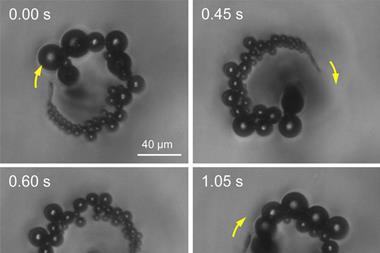

Now, Lakshminarayanan Mahadevan from Harvard University and his team have uncovered the physicochemical laws that drive the growth of silica-carbonate microcrystals. This allowed them to design and fabricate cheap, scalable microarchitectures from a solution of carbon dioxide, barium chloride (BaCl2) and sodium metasilicate (Na2SiO3). By carefully adjusting the solution’s pH, temperature and number of barium carbonate seed crystals, the researchers can grow vase-like structures, helices and even optical microcomponents. The team grew a beam splitter by doping their barium carbonate seeds with the organic dye rhodamine B. The hedgehog-like structure grown from a mixture of strontium chloride (SrCl2) and Na2SiO3 on top of one of these seed crystals can split a beam of light from a fluorescence microscope and direct it to the end of each spike. They also produced helical and trumpet-like structures that act as waveguides, similar to optical fibres.

References

C N Kaplan et al, Science, 2017, 6332, 1395 (DOI: 10.1126/science.aah6350)

No comments yet