A simple, scalable and continuous electrospinning strategy has been developed for producing polymer-coated magnetic nano-stirrer bars that can withstand harsh reaction conditions and also catalyse reactions.

Due to the slow rate of passive diffusion in liquids, chemical reactions often need extra help with mixing, but this is tricky to achieve in small-scale systems. While using channels or external influences (like ultrasound or temperature gradients) have benefits, there are also many disadvantages, including the high cost of incorporating these systems during device fabrication, or potentially destroying the tiny droplets. As an alternative, magnetic field-driven rotating nano-stirrer bars have recently been developed that consist of aligned chains of magnetic nanoparticles coated in a protective shell. However, so far they have only been produced via batch methods that require external magnets during assembly – these techniques are difficult to scale up and there can be inconsistencies between batches. It is also difficult to control the porosity of the shell material, making the stirrer bars vulnerable to harsh conditions.

Now, Xueyang Liu and her colleagues at Nanjing Tech University in China have reported a new synthetic strategy for making magnetic nano-stirrer bars. ‘The biggest advantage of our method is the large scale,’ explains Liu. ‘We have applied an electrospinning method, which is continuous, very fast and able to make large quantities of nano-stirrer bars. Unlike with batch-wise synthesis, you can control the electrospinning time to make more of your product.’

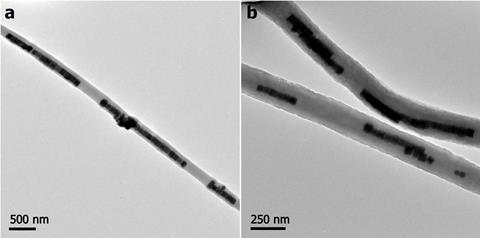

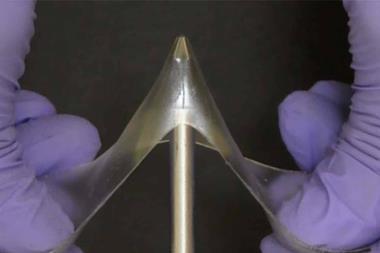

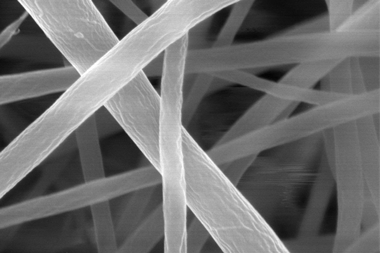

In this new method, polymer-coated Fe3O4 nanofibres are produced via electrospinning and collected in a water bath, where they are treated with ultrasonic waves to break the fibres into short nano-stirrer bars. The shell of the nano-stirrer bars consists of low porosity polyacrylonitrile (PAN), which is highly durable under both acidic and basic conditions. Liu also notes that ‘in this study we use PAN, but we could use PVDF [polyvinylidene fluoride], conductive polymers or polymers with different functional groups.’

Electrospinning is a simple, low cost technique for continuous and scalable syntheses. However, it would ordinarily produce a random dispersion of magnetic nanoparticles inside the fibres, with only weak magnetic coupling, making them unsuitable for nano-stirrer bars. Liu’s team have overcome this problem by confining the magnetic nanoparticles in a minimal amount of polymer and using large nanoparticle sizes to enhance magnetic coupling between the particles.

Elena Shevchenko, a scientist at the Center for Nanoscale Materials at Argonne National Laboratory in the US, says that these nano-stirrer bars could have a wide reaching impact on small-scale systems: ‘When you to try to minimise the amount of solution, there is always a problem with mixing, but introducing nano-stirrer bars that can be externally activated can address these issues. Additionally, the nano-stirrer bars can help to simplify the design of microfluidic platforms and provide a uniform mixing regime of reacting components through the entire process.’

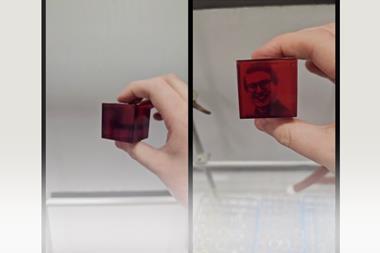

In addition to mixing, the nano-stirrer bars can also function as a catalytic support – the team demonstrated this dual functionality by growing gold nanowires on the surface of the stirrer bars to simultaneously catalyse the reduction of 4-nitrophenol while stirring. Liu says there is still more to explore: ‘A stirrer bar is like a tiny hand that we could use to control the nanostructures, for example, to use it to weave long nanowires. In the future we may also try to grow other structures or catalysts.’

References

This article is free to access until 26 October 2020

Q Ji et al, Chem. Commun., 2020, DOI: 10.1039/d0cc04408c

No comments yet